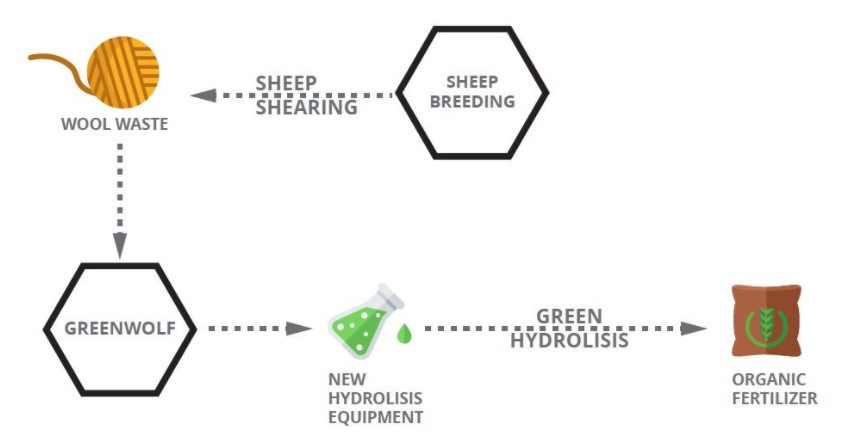

Wool is a by-product of sheep breeding. It is divided into high quality and low-quality wool, called coarse wool that is not suitable for textile uses. The remaining wool is considered as useless waste because it can be a source of infections. The GreenWoolF project, funded by the Life programme, proved the qualities of wool waste and contributed to transform it into an organic fertilizer. The project aimed to demonstrate the effectiveness of a green and sustainable process to convert wool waste into high value fertilizer, which could be of great help to farms throwing away wool-based materials. The process is designed to be cheap and chemical free, since neither alkali, acids, toxic sulphides nor expensive enzymes are used.

1. Context: A large production of wool waste

Coarse wool from EU sheep farming and butchery industry is essentially a worth nothing by-product which is unserviceable for textile application. Nevertheless, annual shearing, which is necessary for the wellbeing of the animals, produces 1.5 to 3kg per head of coarse wool, which represent more than 200 thousand tons per year in the EU. Therefore, poor quality wool produces large volumes of waste which represent an environmental problem, since burning wool for fuel is inefficient because it is self-extinguishing.

Since EU Commission Regulation allows sheep farmers to carry out the scouring process themselves, the pollutant effluents from wool scouring could not be easily controlled resulting in additional environmental problem.

2. GreenWoolF: The conversion of wool wastes into fertilizer

The specific objective of the Life GreenWoolF project is to demonstrate that green hydrolysis with superheated water is an effective and profitable way to convert wool wastes into organic nitrogen fertilisers with good soil amendment properties. This has been carried out by designing, building and testing a transportable demonstration hydrolysis plant. The GreenWoolF treatment process produces fast or slow release fertilisers suitable for organic agriculture and foliar feeding while complying with the EU regulations on wool sterilisation.

The overall objective of the GreenWoolF project has been to demonstrate the viability of converting waste wool into fertiliser using small-scale, local hydrolysis plants. The process reduces transportation costs and eliminates the need for the scouring and disposal of the coarse wool.

Among the long-term objective, the project has wished to:

- Reduce wool waste;

- Exploit renewable resources by recycling organic wastes into value added fertilisers;

- Convert the unusable, greasy wool into an effective soil conditioner fertiliser, an added-value green material with benefits for the environment and profit for the EU livestock sector.

3. The development of an economically-sustainable model

With a pilot in Piedmont, in Italy, the project has demonstrated to have an environmental and socio-economic impact. Indeed, wool waste can be 100% recycled into organic fertiliser using a “green hydrolysis process” with no use of dangerous chemicals. Therefore, it improves the quality of pasture lands with harmless and valuable fertiliser, reducing the use of synthetic fertilisers. In addition, the project has achieved the development of an economically-sustainable management model that takes into account the sheep population and density distribution in the Piedmont region in order to optimise plant size and the added value of the fertiliser produced.

So far, the main project results have included:

- A small demonstration for the treatment of 10 kg of raw wool plant built and placed on a pickup truck for demonstration events and exhibitions; and

- A big demonstration plant for the treatment of 100 Kg of raw wool designed and built for pilot production.

For more information about the GreenWoolf project, please visit: www.life-greenwoolf.eu

4 May 2018